|

|

|

|

Inventory Economic Order Quantity

Back to Productivity Tips History Page

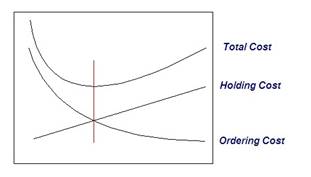

Economic Order Quantity (EOQ) An Economic Order Quantity (EOQ) is an inventory-related evaluation to determine the optimum order quantity which a company should use to ensure that Inventory is not overstocked whilst at the same time maintaining sufficient stock to prevent a stock-out. The objective therefore is to minimise the combined costs of acquiring and carrying inventory. The Formula used is based on the fact that the greater the number of orders placed per year would contain fewer items per order which results in lower Inventory holding costs but would incur a larger overall ordering cost. Conversely, the fewer orders that are placed per year would contain larger quantities per order but have lower overall ordering costs. This however, results in Inventory being held in stock for longer periods resulting in increased holding costs. Combining these two costs you get a graph as shown below:

The EOQ calculation takes into account both the Ordering Cost and the Holding Cost to arrive at the EOQ for the Item. This then provides information to recommend an economic and realistic Suggested Order Quantity. The EOQ formula uses the following parameters:-

________________ Where

We are in the process of including Economic Order Quantity (EOQ) as functionality in Ostendo Operations Software. Ostendo® adds advanced inventory, job costing, manufacturing, service and distribution to your accounting system.

|